- 您现在的位置:买卖IC网 > Sheet目录3886 > PIC16F1827-I/ML (Microchip Technology)IC PIC MCU FLASH 4K 28-QFN

SC16C850

All information provided in this document is subject to legal disclaimers.

NXP B.V. 2010. All rights reserved.

Product data sheet

Rev. 2 — 11 November 2010

50 of 55

NXP Semiconductors

SC16C850

2.5 to 3.3 V UART with 128-byte FIFOs and IrDA encoder/decoder

12.4 Reflow soldering

Key characteristics in reflow soldering are:

Lead-free versus SnPb soldering; note that a lead-free reflow process usually leads to

higher minimum peak temperatures (see Figure 25) than a SnPb process, thus

reducing the process window

Solder paste printing issues including smearing, release, and adjusting the process

window for a mix of large and small components on one board

Reflow temperature profile; this profile includes preheat, reflow (in which the board is

heated to the peak temperature) and cooling down. It is imperative that the peak

temperature is high enough for the solder to make reliable solder joints (a solder paste

characteristic). In addition, the peak temperature must be low enough that the

packages and/or boards are not damaged. The peak temperature of the package

depends on package thickness and volume and is classified in accordance with

Table 39 and 40

Moisture sensitivity precautions, as indicated on the packing, must be respected at all

times.

Studies have shown that small packages reach higher temperatures during reflow

soldering, see Figure 25.

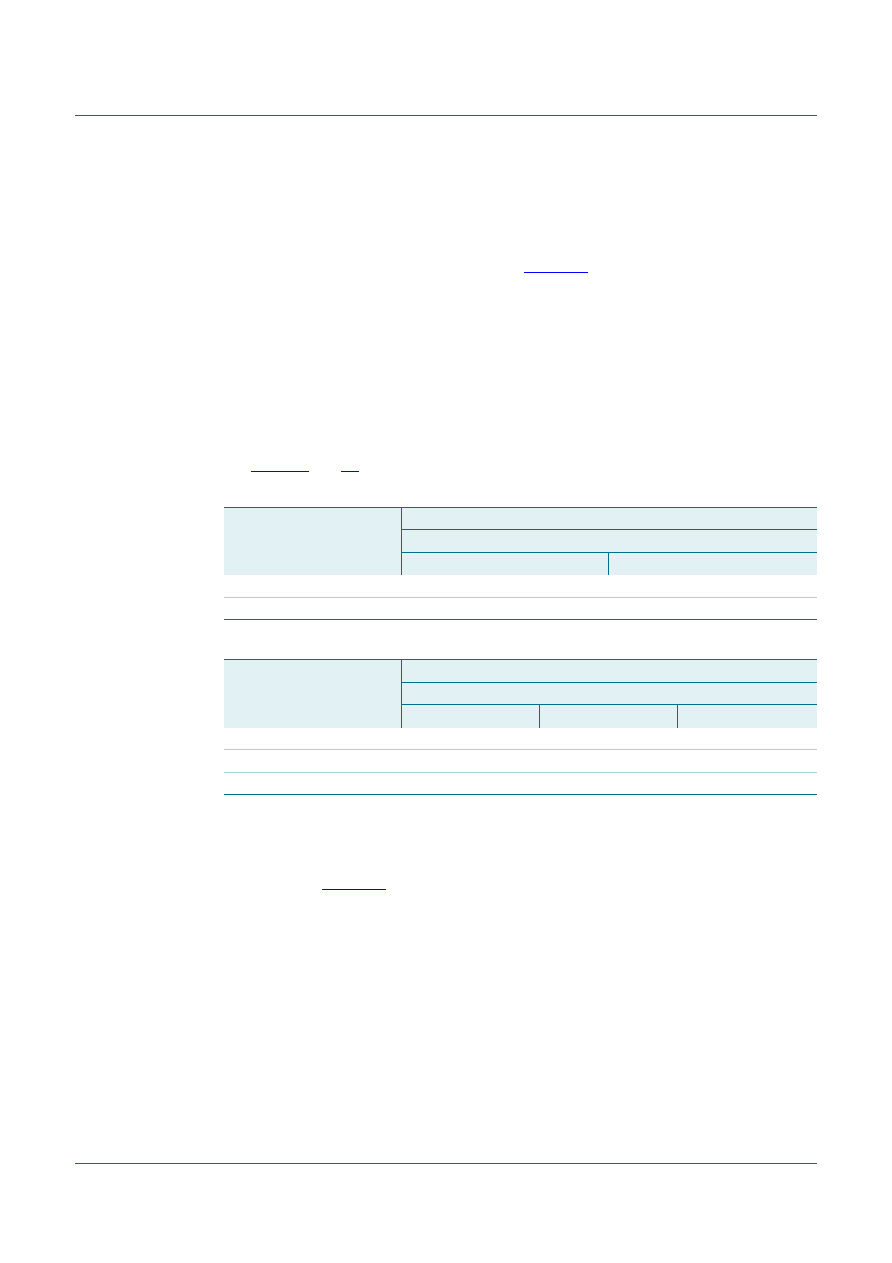

Table 39.

SnPb eutectic process (from J-STD-020C)

Package thickness (mm)

Package reflow temperature (

°C)

Volume (mm3)

< 350

≥ 350

< 2.5

235

220

≥ 2.5

220

Table 40.

Lead-free process (from J-STD-020C)

Package thickness (mm)

Package reflow temperature (

°C)

Volume (mm3)

< 350

350 to 2000

> 2000

< 1.6

260

1.6 to 2.5

260

250

245

> 2.5

250

245

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

PIC16LCE624T-04E/SO

IC MCU CMOS 1K OTP W/EEPRM18SOIC

PIC16LF1827-I/ML

IC PIC MCU FLASH 4K 28-QFN

PIC16LCE624-04E/SS

IC MCU CMOS 1K OTP W/EEPRM20SSOP

PIC16F687-I/P

IC PIC MCU FLASH 2KX14 20DIP

PIC16LF1829-I/SO

MCU PIC 14KB FLASH 20-SOIC

PIC16LCE624-04E/SO

IC MCU CMOS 1K OTP W/EEPRM18SOIC

PIC16F1829-I/SO

MCU PIC 14K FLASH 1K RAM 20SOIC

PIC16F685-I/SS

IC PIC MCU FLASH 4KX14 20SSOP

相关代理商/技术参数

PIC16F1827-I/MQ

功能描述:8位微控制器 -MCU 7KB Flash 384 byte 32 MHz Int. Osc RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT

PIC16F1827-I/MV

功能描述:8位微控制器 -MCU 7KB Flash 384 RAM RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT

PIC16F1827-I/P

功能描述:8位微控制器 -MCU 7KB Flash 384 byte 32 MHz Int. Osc RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT

PIC16F1827-I/SO

功能描述:8位微控制器 -MCU 7KB Flash 384 byte 32 MHz Int. Osc RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT

PIC16F1827-I/SS

功能描述:8位微控制器 -MCU 7KB Flash 384 byte 32 MHz Int. Osc RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT

PIC16F1827T-I/ML

功能描述:8位微控制器 -MCU 7KB Flash 384 byte 32 MHz Int. Osc RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT

PIC16F1827T-I/MQ

功能描述:8位微控制器 -MCU 7KB Flash 384 byte 32 MHz Int. Osc RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT

PIC16F1827T-I/MV

功能描述:8位微控制器 -MCU 7KB Flash 384 RAM RoHS:否 制造商:Silicon Labs 核心:8051 处理器系列:C8051F39x 数据总线宽度:8 bit 最大时钟频率:50 MHz 程序存储器大小:16 KB 数据 RAM 大小:1 KB 片上 ADC:Yes 工作电源电压:1.8 V to 3.6 V 工作温度范围:- 40 C to + 105 C 封装 / 箱体:QFN-20 安装风格:SMD/SMT